Foshan Shunde Shunanhong Machinery Technology Co., Ltd. Date:2023-12-26

The extrusion production line is achieved by extruding a high-temperature and high-pressure plastic melt through a mold, and then cooling it into shape.

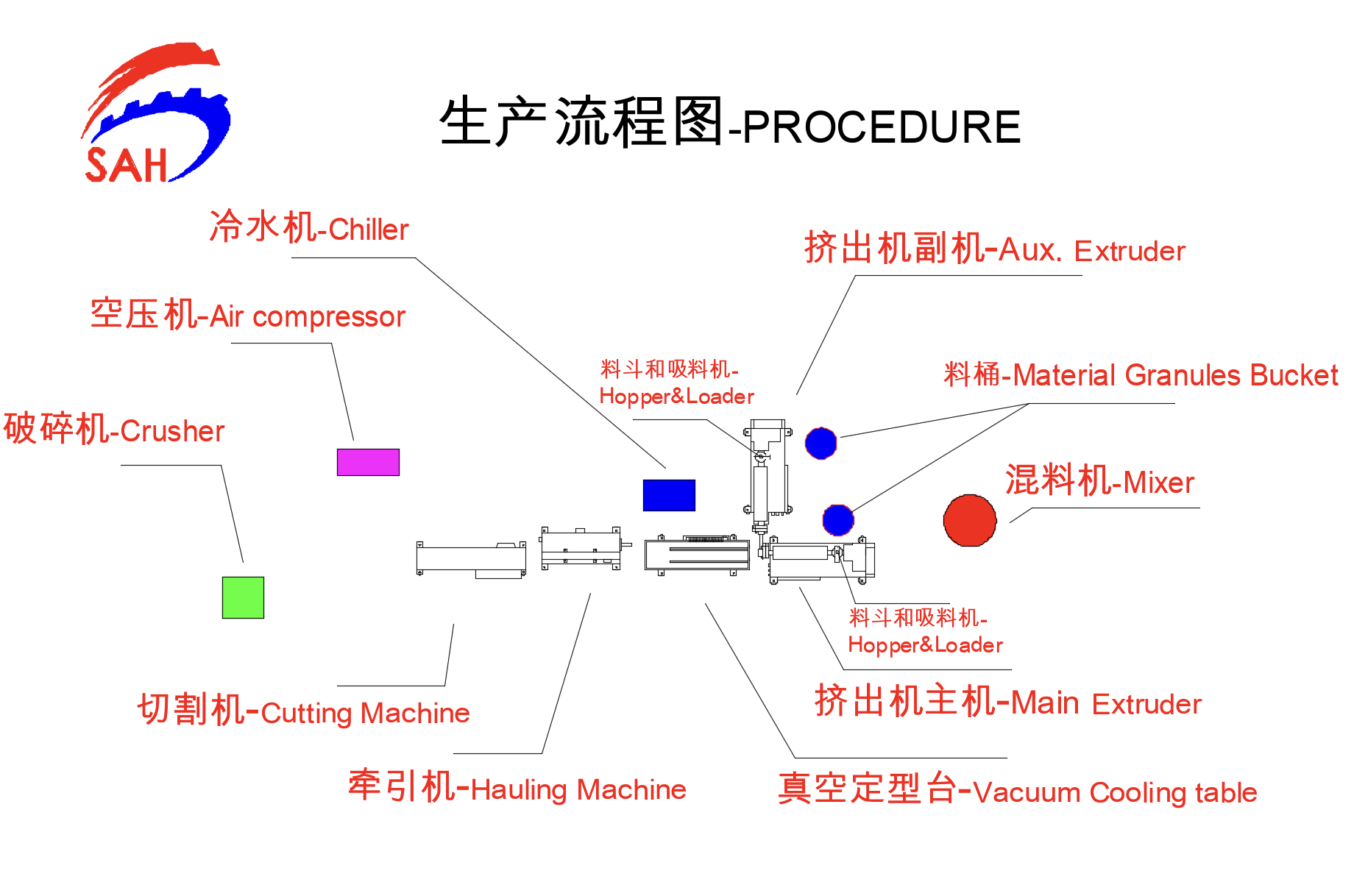

The main process flow of the extrusion production line is as follows:

1. Melting of plastic particles

Firstly, plastic particles are placed into an extruder and melted through heating, mixing, and compression. This step usually requires the use of high temperature and high pressure to achieve a flowing state of plastic particles.

2. Melt extrusion

The melted plastic is extruded through the screw and cylinder in the extruder, and then extruded into a mold with the desired shape. At this point, the mold is usually heated to maintain the fluidity of the melt.

3. Cooling and curing

Once plastic is extruded from the mold, it quickly cools down and solidifies into the desired shape. Usually in extrusion production lines, water or air is used to cool the molds and plastics.

4. Activity cutting or fixed length cutting

After cooling and curing, the plastic is a continuous film or tube that needs to be cut into specific lengths or sizes. This step is usually done by a cutting machine

Complete.

5. Transportation and packaging

Finally, the products that are cut into specific sizes are transferred to the packaging area and packaged with packaging materials for protection and transportation.